Fire-Resistant and Energy-Efficient Fungi-Based Building Materials

Towards Hazard-Mitigating Housing

Publication Date: 2024

Abstract

Fungi-based building materials—including engineered woods and insulation—have properties that could make them more fire resistant and energy efficient than conventional synthetic building materials. This suggests that fungi-based building materials could mitigate risks from fire- and extreme weather-related hazards. To test this proposition, this study cultivated Fusarium oxysporum, a filamentous fungus, using sodium silicate solution (as a silicon source) and enriched with nutrient and agricultural waste. Fungal films and fungi-based composites were prepared for fire-resistant and thermal property testing in a laboratory setting and computer simulations were developed to compare the energy consumption of homes made from fungi-based building materials to homes made from conventional synthetic ones. The fire resistance tests revealed that fungi grown with 1% and 2% silicon source had significantly higher ignition temperatures and reduced flame heights. Furthermore, using fungi-based composite insulation in buildings located could save $17.84 per month compared to conventional insulation, reducing energy consumption. In terms of annual cooling energy consumption, buildings using fungi-based insulation show decreased energy use across different climate zones. Specifically, energy savings were observed in various cities: Chicago (91.26 kWh), Tampa (12.57 kWh), San Francisco (344.80 kWh), St. Paul (90.40 kWh), Portland (116.82 kWh), and Anchorage (290.53 kWh). Beyond mitigating fire and extreme weather hazards, the growth of fungi-based materials from agricultural waste presents a novel and cost-effective approach to producing multifunctional building materials. This has a tangible social impact on housing quality in the United States, especially in low-income areas. Overall, this project advances hazard mitigation knowledge and promotes sustainable building practices.

Introduction

Climate change has intensified extreme weather events and fire hazards in the United States, significantly impacting the housing sector. Wider adoption of fire-resistant building materials that mitigate hazard risk is urgently needed. Synthetic building materials—which have been promoted as having fire-resistant properties—are under scrutiny for their use and release of harmful substances, posing risks to human health. Additionally, synthetic materials often fail to degrade fully and adversely affect the environment by leaching toxins.

To address such challenges and enhance fire-resistant housing, this study developed fungi-based building materials grown from silicon sources and agricultural waste. We developed and tested two types of fungi-based building materials—engineered woods and insulation—in a laboratory setting and using a computer simulation. In the laboratory, the fire-resistant properties of fungi-based materials were characterized by ignition temperature, ignition time, flame duration, and flame height. Results indicate that fungi grown with 1% and 2% silicon sources significantly increased ignition temperature and time, while reducing flame duration and height. Using a computer simulation, we evaluated the thermal properties of fungi-based insulation materials in order to assess how their implementation in buildings in select U.S. cities would affect household energy consumption and electricity costs. Compared to conventional insulation, fungi-based composite helped maintain indoor temperature within a relatively comfortable range and thereby saved $17.84 monthly in energy costs. The findings from the model showed that fungi-based insulation materials reduced household energy consumption for cooling and heating.

Literature Review

There were 360,000 home structure fires in 2022 in the United States, which constitutes 24% of all fires reported that year (U.S. Fire Administration, 20231). The housing fires caused $10.5 billion in direct property damage, which was 59% of the total property damage recorded in 2022. As urbanization continues unabated, home builders increasingly rely on housing materials made from petroleum-derived synthetic polymers, largely because of their cost-effectiveness and lightweight characteristics (Kidalova et al., 20122).

Hazard and Health Risks Associated With Synthetic Building Materials

Synthetic building materials like insulation foams and resin-based engineered woods (which use synthetic resin-bonded sawdust as wood panels) exemplify the widespread utilization of petroleum-based products in construction. However, the rising demand for synthetic wood-based panels and insulation materials in construction has raised concerns regarding their combustibility. All wood-based boards, when exposed to fire, ignite and release heat, potentially exacerbating the fire under certain conditions (Yang et al., 20023). Houses constructed with synthetic wood-based panels, however, collapse more than three times faster than those built with solid wood constructions (Jones et al., 20184). Similarly, petroleum-based insulation foams, when ignited, burn rapidly, generating intense heat, dense smoke, and gases such as carbon monoxide and toluene. These byproducts are not only irritating but also flammable and toxic (Occupational Safety and Health Administration, 19895; Stec & Hull, 20116). The significant release of heat and toxic smoke from synthetic housing materials poses a serious threat to the safety of people’s lives and properties (Zhou et al., 20167).

Previous research efforts have focused on developing flame-retardant agents to mitigate the fire hazards associated with building materials. For instance, halogen flame retardants, including brominated flame retardants, have proven effective in bulk building materials. However, there is growing concern about their use due to significant biotoxicity (Fan, 20098; Messer, 20109). Another example of common flame-retardant agents includes thermosetting resins, which have been effective in reducing heat release and suppressing smoke when applied to insulation materials (Cao et al., 201710). However, these methods are not considered promising due to their utilization and subsequent release of formaldehyde, which poses significant harm to the human body. Additionally, their durability is insufficient for long-term effectiveness (Hua et al., 202111). There is an urgent need for developing new building materials that do not endanger people’s health or the environment and reduce hazard risk. These materials, however, must also be efficient and cost effective if they are to be viable in the market.

Fungi-Based Building Materials

Fungi-based composites have emerged as promising candidates for insulation materials in building applications, aiming to enhance energy efficiency and sustainability compared to conventional insulation methods. This innovative approach leverages the natural growth and properties of fungal mycelium to create lightweight, biodegradable materials with excellent thermal insulation properties. In contrast to conventional insulation materials that rely on synthetic fibers or mineral-based products, fungi-based composites utilize organic substrates such as agricultural waste or biomass, which are readily available and renewable. The growth process involves the cultivation of fungal mycelium on these substrates, forming a dense network that enhances thermal resistance.

Previous research by the Principal Investigator’s showed that the fungal strain Fusarium oxysporum can effectively develop fungal fibers when grown in the culture medium containing silicon source (Zhang et al., 202112). Additionally, materials cultivated through this fungal process exhibit enhanced thermal stability and improved fire resistance. The same research also showed composite materials developed by cultivating fungi with rye berries resulted in viable candidates for fungi-based insulation materials. The current study builds on the previous investigation by testing the hypothesis that cultivating fungi with silicon-rich agricultural waste, such as rice hulls, will generate fungi-based housing materials with substantial fire-resistant and thermal properties. Utilizing such fungi-based building materials would contribute to fire-disaster mitigation, environmental adaptation, and cost-effectiveness.

Research Questions

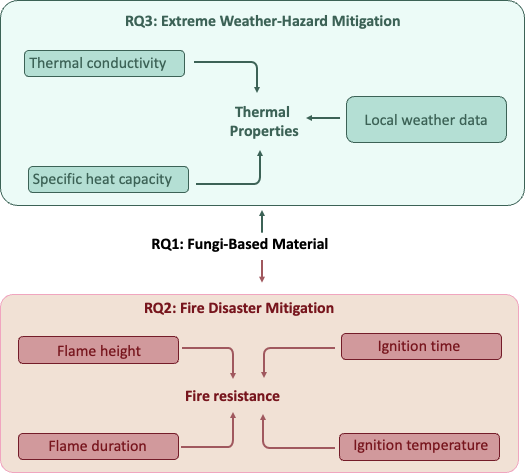

In this project, three research questions were assessed:

How do fungi grow in culture medium rich in varying concentrations of silicon sources and what are the physical properties of fungi-based materials?

What is the ignition temperature and flame height of fungi-based materials, and how do these materials perform under fire conditions?

What are the thermal properties of fungi-based materials, and how do they impact the energy consumption and electricity costs in housing constructed with these materials, particularly in response to different weather conditions?

Research Design

The fungi used in this study was Fusarium oxysporum, a Bio-safety Level 1 biological agent, which is the classification that the Centers for Disease Control and Prevention (2020)13 uses for those biological agents that require only the most basic laboratory safety measures because they are not known to cause illness in healthy adults (p. 4). The fungi spawn, containing hyphal vegetative tissue and spores, was purchased from American Type Culture Collection (ATCC). The fungi-based materials were grown within a lab-controlled environment. Two sampling strategies were implemented. The first involved growing a thin film of fungi, which enables precise measurement of ignition temperature and flame spread speed. (Bulk materials do not allow for such precise measurement.) The fungal colony was naturally grown in Petri dishes fed with a culture medium (Potato Dextrose Broth and silicon-rich agricultural waste). Fungal inoculums with a diameter of 2 mm were cut and this harvested thin film of fungi underwent characterization for fire-resistant properties. The second sampling strategy involved growing a fungi-based composite. Fungi and silicon-rich agricultural waste was placed in molds for incubation. After 7 days of growth, the composites were placed in the oven for 24 hours at 65 °C to eliminate any living microbes. The resulting fungi-based composites were used for characterizing environmental adaptation.

The research flow chart for the project is shown in Figure 1. The investigation involved extensive laboratory investigations, where the fungi-based materials were developed and characterization of their fire-resistant and insulating properties took place. Within the laboratory setting, critical parameters such as ignition temperature were gathered using thermal sensors. The burning process of materials was captured through video recording, with subsequent image analysis extracting flame height, flame spread speed, and flame duration. Multiple samples were thoughtfully prepared for testing, and statistical analysis was applied to calculate the ignition rate of fungi-based materials.

Figure 1. Research Design Flow Chart

To complement the laboratory-based research, the investigation also included simulations of how the building materials would function during extreme weather events. Weather data from various climate zones in the United States was sourced from the EnergyPlus weather database (National Renewable Energy Laboratory, n.d.14). Selected locations from diverse climate zones were then utilized for building simulations, contributing to a deeper understanding of the environmental adaptability of the fungi-based materials.

Laboratory-Based Methods

The Preparation of Fungal Film

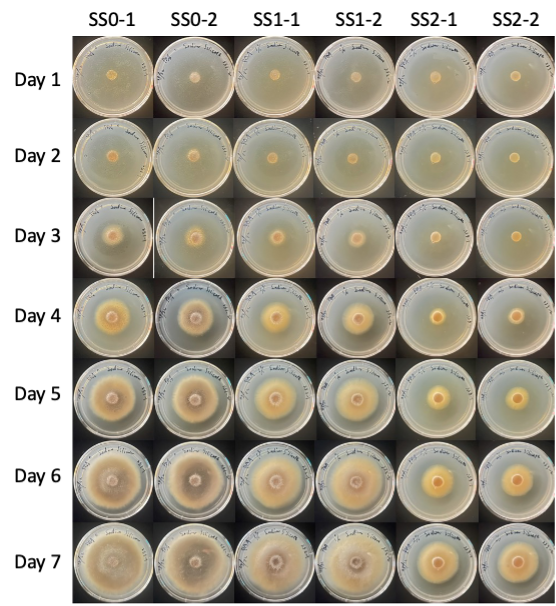

Experiments initially used both a liquid nutrient, Potato Dextrose Broth, and a semi-solid nutrient, Potato Dextrose Agar, to prepare fungal samples. However, results showed that achieving uniform thickness of fungal growth in the liquid broth was challenging. (Refer to Appendix A for a full explanation of results). Therefore, Fusarium oxysporum (ATCC-MYA-1198) was inoculated onto the semi-solid Potato Dextrose Agar in Petri dishes with a 60 mm diameter. As detailed in Table 1, the silicon source (sodium silicate) was incorporated into the Potato Dextrose Agar to cultivate fungi at 0%, 1%, and 2% volume ratios. Two samples at each of the three silicon source percentages were prepared, for a total of six samples in the experiment.

Table 1. Fusarium Oxysporum Growing With Potato Dextrose Agar and Silicon Source

The growth patterns of the fungal samples are illustrated in Figure 2. The images were captured each day over the 7-day incubation period to document mycelium development.

Figure 2. Fungal Growth on Potato Dextrose Agar

To assess the growth behavior of Fusarium oxysporum on different substrates with varying silicon concentrations, the diameters of the fungal films were measured in two perpendicular directions. The average diameters were compiled in Table 2.

Table 2. The Growth Diameter of Mycelium (mm)

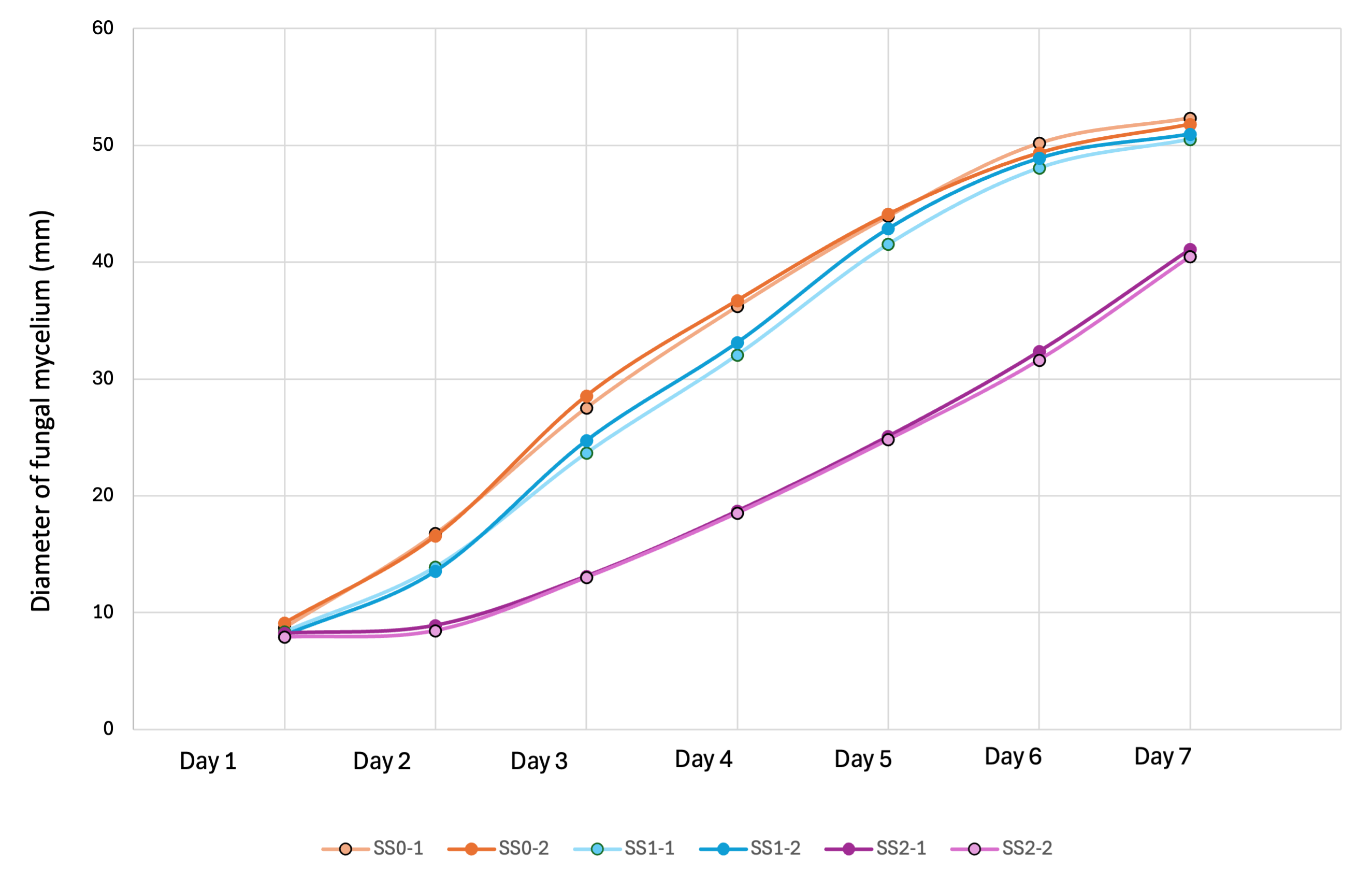

Figure 3 illustrates the growth rates of fungi in the SS0, SS1, and SS2 groups, highlighting the impact of the silicon source on fungal growth. In terms of growth pattern, fungal development in SS0 and SS1 groups initially showed a linear increase in the first 2 days. However, when 2% silicon was added to the Potato Dextrose Agar, fungal growth exhibited a slower and more stagnant rate thereafter. Overall, increasing silicon concentration inhibited fungal growth rates, suggesting that silicon absorption delayed the surface area expansion of fungal mycelium. This inhibitory effect was more pronounced in fungi cultivated with higher silicon concentrations. Nevertheless, all three groups achieved approximately 50% coverage of the Petri dish, which made them suitable for fire resistance testing. After 7 days of growth, fungal films cultivated with 0%, 1%, and 2% silicon were harvested and subjected to 40°C oven drying for 24 hours to minimize moisture-related influences.

Figure 3. Fungal Growth Rates on Potato Dextrose Agar

The Preparation of Fungi-Based Composites

Composite samples were created through a series of steps. Initially, fungal spores were cultivated in Potato Dextrose Broth solution for 3 days until reaching an optimal spore concentration. This spore-infused Potato Dextrose Broth solution was then mixed with wheat straw inside a filter patch bag for 4 days. Subsequently, the myceliated feedstocks were transferred into sterilized silicone gel molds. Over the next 4 days, hyphae from the fungal mycelium bonded with the wheat straw, forming a progressively denser network. The substrate was allowed to grow within the molds for an additional 4 days. Throughout this process, the incubation conditions were tightly controlled at 65% relative humidity and 25°C to facilitate the formation of insulation bricks composed of fungal mycelium. Following this growth phase, the bricks underwent a 24-hour heat treatment at 65°C in an oven to eliminate any biological materials present in the mycelium composites. Figure 4 illustrates the detailed procedure for preparing these samples.

Figure 4. The Preparation Process of Fungi-Based Composites

Fire Resistance Testing

The fungal films cultivated with varying concentrations of silicon source were harvested after 7 days for fire resistance testing. Each sample was placed on a metallic grid, and a cone underneath provided a constant heat flux of 17.5 KW/m2. Upon placement, a thermocouple with a diameter of 0.127 mm was affixed to the films’ surface to measure ignition temperature. Additionally, the maximum flame height was determined using image analysis.

Thermal Property Testing

The thermal conductivity of the fungi-based composite was measured using the divided bar method. An acrylic glass, known for its thermal conductivity of 0.17 W/(m·K), served as the reference sample. The thermal conductivity of the fungi-based composite was determined to be 0.07 W/(m·K). Additionally, the laboratory tests showed that the average specific heat capacity of the fungi-based composite was 9,000 J/(kg·K). These thermal property results were used in the computer simulation to model the household energy consumption and electricity costs associated with using fungi-based insulation materials. See Appendix B for a full description of the thermal conductivity and specific heat capacity testing setup.

Computational Modeling

Energy Consumption Simulation

A multiphysics model—which is a computational model that tests various interactions simultaneously—was developed to compare the indoor temperature fluctuation and energy consumption of buildings using fungi-based insulation versus conventional insulation. In recent years, significant progress has been made in establishing the theoretical basis for thermo-hydraulic processes. This involves modeling two key physical fields—thermal and hydraulic—using mixture theory to accurately describe fundamental conservation principles. See Appendix C for a full description of the theoretical framework for the heat and moisture balance equations.

The building geometry used to evaluate temperature and moisture changes is illustrated in Figure 5. Appendix D provides the envelope specifications for buildings with regular insulation and fungi-based composite insulation as well as the input temperatures.

Figure 5. Geometry of Building Used for Simulation

Simulation of Household Electricity Costs

The multiphysics simulation was used to calculate energy consumption based on indoor temperature changes. The following equation was used to estimate energy usage. The heating set-point temperature is 20°C; the cooling set-point temperature is 26°C.

U = Cpm ΔT = CpρV ΔT

where Cp is the sir specific heat capacity (1.005 kJ/(kg K)); m is the mass of air in the building; ρ is the air density (1.225 kg/m3); ΔT is the temperature differential, which is 655.46K in regular building while it is 454K in fungi-based building.

Results

Fire Resistance

Fire resistance was evaluated based on several parameters: time to ignition, ignition temperature, flame height, and flame duration (see Table 3). Time to ignition marked the moment when flames first appeared on the sample’s surface, while ignition temperature was the temperature at which ignition occurred. Flame height referred to the maximum height reached by the flame, and flame duration was the duration of the flame’s presence.

Table 3. Fire Resistant Evaluation of Fungal Films

According to the fire resistance test results in Table 3, ignition occurred within the 3 seconds for the sample with no silicon source (SS0). The addition of 1% and 2% silicon source significantly delayed ignition by 1 to 5 seconds. As Figure 6 shows, the SS0 sample exhibited a high flame with dense smoke. Moreover, as detailed in the results table, the ignition temperature was 183.2 °C and the flame height was 23.42 mm. Fungal fibers cultivated with 1% and 2% silicon source, on the other hand, showed notably higher ignition temperatures—285.1 °C and 315.8 °C, respectively. The ignition temperatures of samples with silicon source, in other words, were 56% to 72% higher than the sample without silicon. The flame heights of the samples with silicon were also much lower, measuring 15.09 mm (SS1) and 10.85 mm (SS2), which are 8.33 mm and 12.57 mm less than the sample without silicon. These characteristics indicate that fungal fibers grown with silicon source achieved enhanced fire resistance by decreasing the likelihood of ignition and reducing flame intensity. Moreover, higher concentrations of silicon source in the substrate further improved the fire resistance of fungal fibers.

Figure 6. Fire Resistant Behavior of Fungal Films

Average Indoor Temperature in the Building

To directly observe the thermal insulation effects, indoor temperatures were modeled for buildings using fungi-based composite and regular insulation materials. The models predicted the indoor temperatures in buildings alongside outside air temperatures during representative winter and summer days. Figure 7 models temperatures in winter conditions. The lowest outside air temperature was 255 K (-18.15 °C). With regular insulation, the lowest indoor temperature moderated to 287 K (13.85 °C), whereas with fungi-based composite insulation, it reached 289 K (15.85 °C). The highest outdoor air temperature recorded was 301 K (27.85 °C), resulting in maximum indoor temperatures of 293 K (19.85 °C) with regular insulation and 295 K (21.85 °C) with fungi-based composite insulation.

Figure 7. Comparison of Thermal Effects of Conventional Foam Insulation and Fungi-Based Insulation in Winter Conditions

Comparing insulation materials during summer (Figure 8), the highest outdoor air temperature was 321 K (47.85 °C). Indoor temperatures peaked at 299 K (25.85 °C) with regular insulation and 297 K (23.85 °C) with fungi-based composite insulation. In both winter and summer scenarios, fungi-based insulation exhibited smaller fluctuations in indoor temperature compared to conventional insulation materials.

Figure 8. Comparison of Thermal Effects of Conventional Foam Insulation and Fungi-Based Insulation in Summer Conditions

Impact on Energy Consumption for Heating and Cooling

In addition to indoor temperature control, we conducted a comparison of annual energy consumption for heating and cooling between buildings with conventional insulation and those using fungi-based insulation. This section explains our findings that buildings with fungi-based insulation generally require less energy for heating and cooling.

Figure 9 depicts the annual energy consumption predicted for cooling buildings with regular foam or fungi-based insulation in select U.S. cities With the exception of Baltimore, the model predicts that annual energy consumption for cooling is lower when buildings use fungi-based insulation materials.

Figure 9. Comparison of Annual Energy Consumption for Cooling in Buildings With Regular and Fungi-Based Insulation in Select U.S. Cities

Figure 10 depicts the annual energy consumption predicted for cooling buildings with regular foam or fungi-based insulation in select U.S. cities. Notably, fungi-based insulation showed superior performance in reducing heating energy consumption across various regions, particularly in colder climates.

Figure 10. Comparison of Annual Energy Consumption for Heating in Buildings With Regular and Fungi-Based Insulation in Select U.S. Cities

Figure 11 shows the annual reduction in energy consumption for heating and cooling buildings insulated with fungi-based materials. Among the cities evaluated, the fungi-based insulation yielded the highest annual reduction in energy used for heating in Portland (1287.78 kWh), followed by Baltimore (1156.56 kWh), Anchorage (1057.95 kWh), St. Paul (591.47 kWh), and Chicago (575.14 kWh). Conversely, the reduction in energy used for heating was more modest in warmer regions such as Tampa and San Francisco, amounting to only 46.11 kWh and 103.03 kWh, respectively.

Figure 11. Annual Reduction in Energy Consumption in Buildings With Fungi-Based Insulation in Select U.S. Cities

Regarding energy consumption for cooling, fungi-based insulation resulted in decreases in six cities. Annual cooling energy savings were observed in Chicago (91.26 kWh), Tampa (12.57 kWh), San Francisco (344.80 kWh), St. Paul (90.40 kWh), Portland (116.82 kWh), and Anchorage (290.53 kWh). However, an increase of 9.38 kWh in cooling energy consumption was noted in Baltimore when fungi-based insulation was used.

These results underscore the potential of fungi-based insulation to significantly reduce energy consumption for both heating and cooling in buildings, particularly in colder climates, while acknowledging variations in performance across different geographic locations.

Impact on Electricity Costs

As indicated in Table 4, employing fungi-based insulation in buildings could result in savings of $17.84 per month compared to buildings with regular insulation. This cost-saving benefit underscores the potential energy-saving and economic advantage of adopting fungi-based insulation for improved energy efficiency.

Table 4. Electricity Cost per Month Based on Multiphysics Simulation

kj |

KWh |

|||

a The exact unit cost is 13.31 cents.

Concluscions

This study demonstrates the promising potential of fungi-based materials as multifunctional solutions for mitigating fire and extreme weather disasters, while promoting sustainable building practices in the United States.

Implications for Practice or Policy

The implications of using fungi-based materials in practice and policy are multifaceted and impactful. First, enhancing fire resistance through fungi-based materials addresses critical safety concerns in building construction. By increasing ignition temperatures and reducing flame heights, these materials contribute to safer built environments, particularly in areas prone to wildfires or other fire hazards exacerbated by climate change. Second, the demonstrated energy savings from fungi-based insulation highlight their potential to reduce greenhouse gas emissions and operational costs for building owners and occupants. The study suggests fungi-based insulation materials could be effective ways to advance energy-efficient buildings and energy conservation policies. Third, the affordability and accessibility of fungi-based materials can improve housing quality, particularly in underserved and low-income communities. By offering cost-effective solutions that enhance thermal comfort and safety, these materials contribute to equitable access to resilient and sustainable housing solutions. Finally, integrating fungi-based materials into building codes and standards can incentivize their adoption across the construction industry. Policy frameworks that promote research, development, and deployment of sustainable building materials can accelerate market acceptance and scale-up production of fungi-based products.

Limitations

This study offers a proof of concept for using fungi-based materials in mitigating fire and extreme weather hazards. However, due to time constraints, the fire resistance testing and evaluation of energy consumption were conducted separately. Furthermore, this study primarily focuses on laboratory-scale experiments and simulations. Scaling up fungi-based materials to meet real-world construction demands, including durability over time and in various environmental conditions, remains a significant challenge.

Future Research Directions

Moving forward, several avenues for future research on fungi-based materials in building applications can be explored. We would like to investigate optimal cultivation conditions for fungi to enhance material properties such as fire resistance, thermal insulation, and structural integrity. We would also like to conduct comprehensive studies to assess the long-term durability and performance of fungi-based materials in real-world conditions, including exposure to varying climates, moisture levels, and mechanical stresses. Furthermore, we would like to conduct life cycle assessments to evaluate the environmental impacts of fungi-based materials across their entire life cycle, from production and use to disposal or recycling. We would compare these impacts with traditional insulation materials. By addressing these research directions, the field can advance towards realizing the full potential of fungi-based materials as viable, sustainable alternatives in the construction industry, contributing to resilient and environmentally friendly built environments.

References

-

U.S. Fire Administration. (2023). Fire loss in the United States. https://www.nfpa.org/education-and-research/research/nfpa-research/fire-statistical-reports/fire-loss-in-the-united-states ↩

-

Kidalova, L., Stevulova, N., Terpakova, E., & Sicakova, A. (2012). Utilization of alternative materials in lightweight composites. Journal of Cleaner Production, 34, 116–119. https://doi.org/10.1016/j.jclepro.2012.01.031 ↩

-

Yang, H.-S., Kim, D.-J., & Kim, H.-J. (2002). Combustion and mechanical properties of fire-retardant treated wastepaper board for interior finishing material. Journal of Fire Sciences, 20(6), 505–517. https://doi.org/10.1177/0734904102020006471 ↩

-

Jones, M., Bhat, T., Huynh, T., Kandare, E., Yuen, R., Wang, C. H., & John, S. (2018). Waste-derived low-cost mycelium composite construction materials with improved fire safety. Fire and Materials, 42(7), 816–825. https://doi.org/10.1002/fam.2637 ↩

-

Occupational Safety and Health Administration. (1989). OSHA hazard information bulletins fire hazard of polyurethane and other organic foam insulation aboard ships and in construction. https://www.osha.gov/publications/hib19890510 ↩

-

Stec, A. A., & Hull, T. R. (2011). Assessment of the fire toxicity of building insulation materials. Energy and Buildings, 43(2), 498–506. https://doi.org/10.1016/j.enbuild.2010.10.015 ↩

-

Zhou, K., Gui, Z., & Hu, Y. (2016). The influence of graphene-based smoke suppression agents on reduced fire hazards of polystyrene composites. Composites Part A: Applied Science and Manufacturing, 80, 217–227. https://doi.org/10.1016/j.compositesa.2015.10.029 ↩

-

Fan, Z. (2009). Metabolism and transformation of brominated flame retardants existing in environment and human body. Progress in Chemistry, 21(6), 1364-1372. https://manu56.magtech.com.cn/progchem/EN/abstract/abstract10025.shtml ↩

-

Messer, A. (2010). Mini-review: Polybrominated diphenyl ether (PBDE) flame retardants as potential autism risk factors. Physiology & Behavior, 100(3), 245–249. https://doi.org/10.1016/j.physbeh.2010.01.011 ↩

-

Cao, B., Gu, X., Song, X., Jin, X., Liu, X., Liu, X., Sun, J., & Zhang, S. (2017). The flammability of expandable polystyrene foams coated with melamine modified urea formaldehyde resin. Journal of Applied Polymer Science, 134(5). https://doi.org/10.1002/app.44423 ↩

-

Hua, Y., Ma, C., Huang, S., Wang, R., Chen, J., Guo, Q., Zhou, J., Zhu, H., & Li, W. (2021). Toxic effects of formaldehyde and the protective effect of docosahexaenoic acid in Drosophila. Translational Neuroscience, 12(1), 351–361. https://doi.org/10.1515/tnsci-2020-0186 ↩

-

Zhang, X., Fan, X., Han, C., Li, Y., Price, E., Wnek, G., Liao, Y.-T. T., & Yu, X. (Bill). (2021). Novel strategies to grow natural fibers with improved thermal stability and fire resistance. Journal of Cleaner Production, 320, 128729. https://doi.org/10.1016/j.jclepro.2021.128729 ↩

-

Centers for Disease Control and Prevention. (2020, June). Biosafety in Microbiological and Biomedical Laboratories (6th ed.). U.S. Department of Health and Human Services, National Institutes of Health. https://www.cdc.gov/labs/pdf/SF__19_308133-A_BMBL6_00-BOOK-WEB-final-3.pdf ↩

-

National Renewable Energy Laboratory. (n.d.). Energyplus weather data [Data base]. U.S. Department of Energy. https://energyplus.net/weather ↩

Zhang, X. (2024). Fire-Resistant and Energy-Efficient Fungi-Based Building Materials: Towards Hazard-Mitigating Housing. (Natural Hazards Center Mitigation Matters Research Report Series, Report 19). Natural Hazards Center, University of Colorado Boulder. https://hazards.colorado.edu/mitigation-matters-report/fire-resistant-and-energy-efficient-fungi-based-building-materials